The aim of this study was to optimize the main parameters of the process for production of glass ceramics from fly ash and waste glass by using response surface method 19.

Optimisation of sintered glass ceramics from an industrial waste glass.

Enrico bernardo giovanni scarinci erika edme ulysse michon nicholas planty fast sintered gehlenite glass ceramics from plasma vitrified municipal solid waste incinerator fly ashes journal of the american ceramic society 10 1111 j 1551 2916 2008 02892 x 92 2 528 530 2009.

20 28 in addition the coefficient of thermal expansion 9 5 10 6 c 1 is also comparable to the ones already measured in waste derived glass ceramic materials.

Request pdf optimisation of sintered glass ceramics from an industrial waste glass industrial plasma melting of municipal solid waste msw incinerator fly ashes leads to a glass that may be.

The sintered materials exhibit a well developed and reproducible glass ceramic microstructure comprising a silicate matrix with dispersed crystalline phases.

Two step thermal process.

Synthesis of an original glass composition with specific sinter.

Industrial plasma melting of municipal solid waste msw incinerator fly ashes leads to a glass that may be easily crystallised to gehlenite glass ceramics by the sintering of fine glass powders.

The hazardous industrial waste used may range from 50 to 70 percent of the raw material used which is higher in comparison to other similar technologies.

The matrix was b 2 o 3 fe 2 o 3 cao sio 2 al 2 o 3 glass with one of the crystalline phases enriched in metals especially iron and titanium.

Sintered glass ceramic samples of optimized composition glass clay waste weight proportion equal to 50 30 20 featured a water absorption below 2 a good specific strength and above all a substantially unchanged f content compared to the starting mixture.

The production of glass ceramic materials based on inorganic industrial waste generated by different industries is a promising line and has been used very successfully to crystallize important ceramics from the glass phase.

The obtained glass ceramics can be potentially used for industrial buildings because of the sufficient mechanical strength.

The technology of granite like glass ceramics from hazardous industrial wastes is based on the following steps.

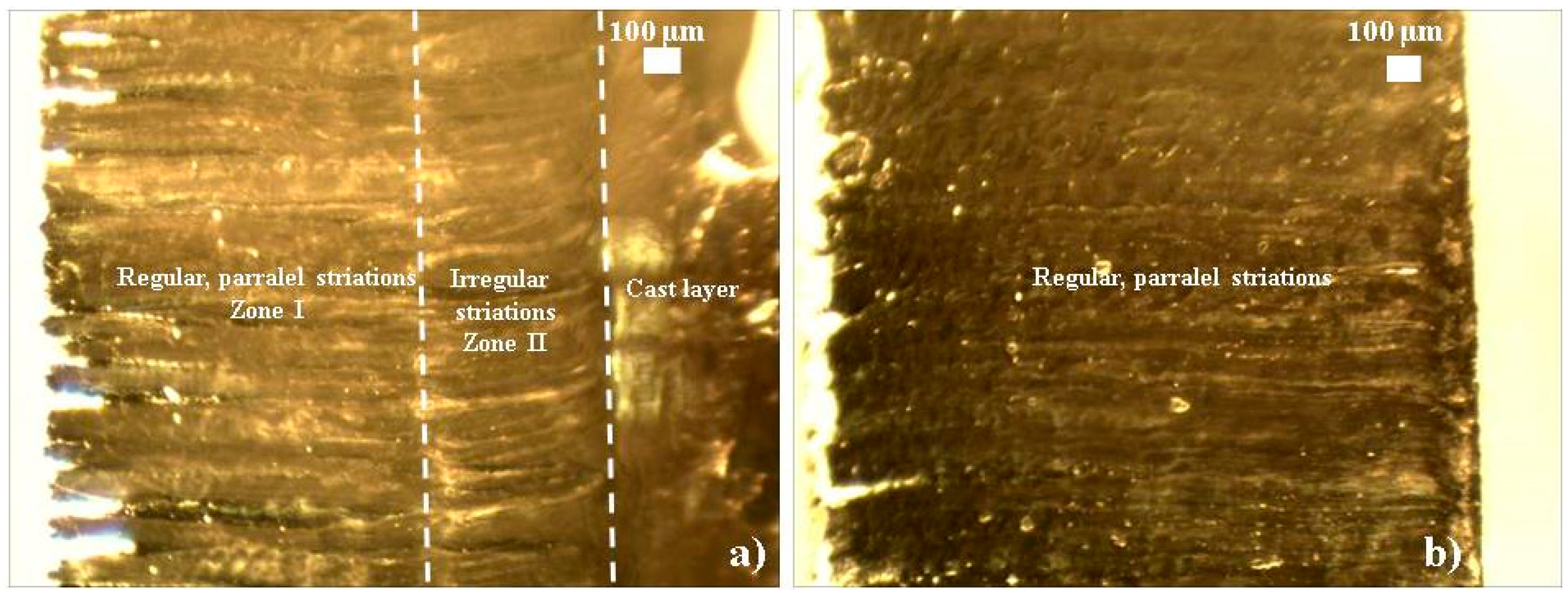

28 figure 5a shows the typical.